New project in the UK’s Faraday Battery Challenge programme set to develop a ground-breaking new technology for lithium-ion battery current collectors

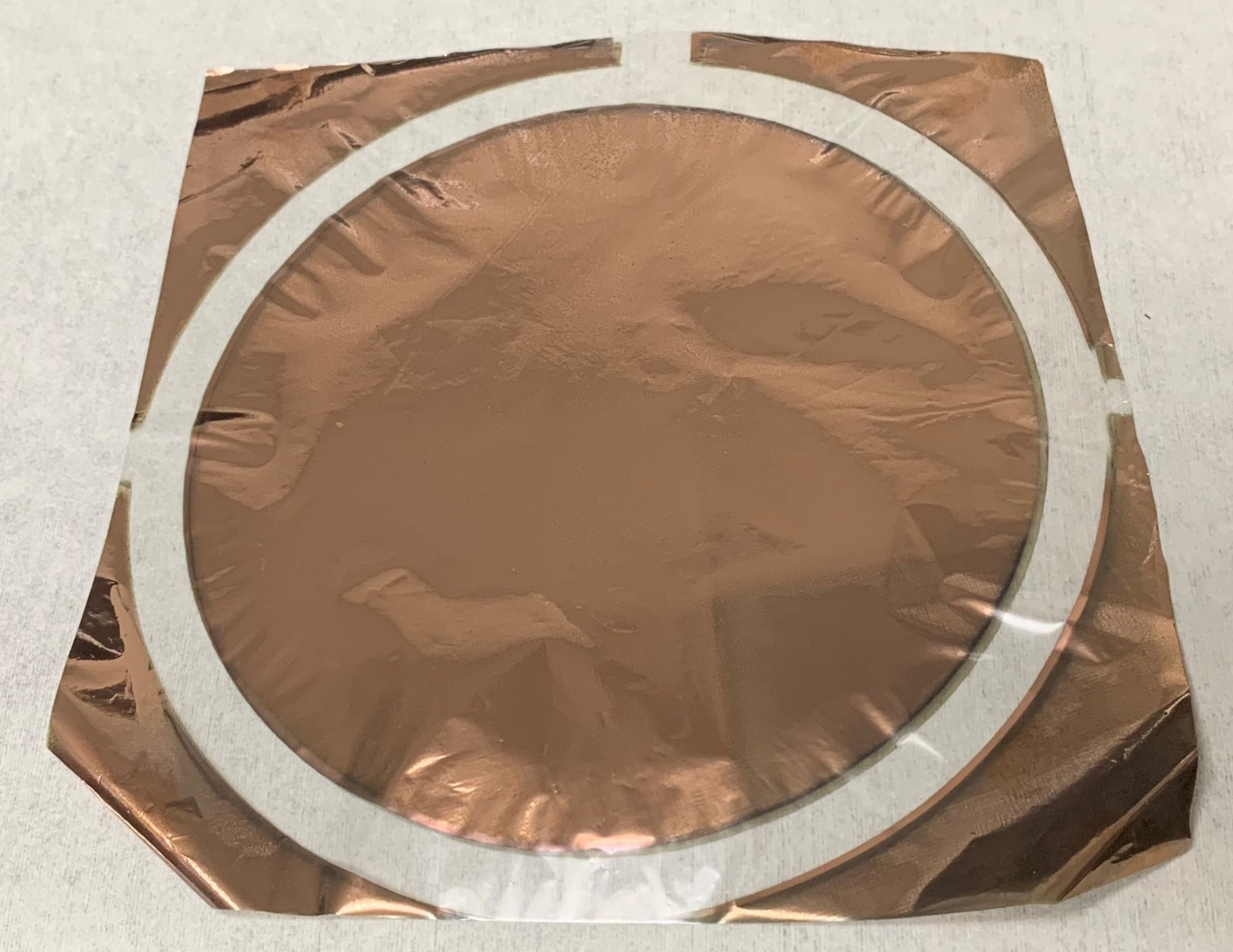

Battery current collectors are considered a mature technology, with engineered metal foils typically used to carry currents in today’s lithium-ion batteries. However, current collectors comprise approximately 10-15% of the total battery cell mass and do not actively contribute to the battery capacity. This is about to change with the new technology, which can offer unprecedented improvement in the cell energy density and safety. Additionally, it can be used with any battery chemistry. Battery cell manufacturers will gain access to new cell components, allowing them to develop and produce batteries with improved performance.

The project is a collaboration between DuPont Teijin Films UK Ltd. (DTF), a well-known innovative polyester film company with established production capabilities and global reach; DZP Technologies Ltd. and Plasma App Ltd., both research intensive SMEs with expertise in battery materials and processes; and WMG at the University of Warwick, the UK’s centre of excellence for lithium-ion battery research and pilot-scale production.

The project aims to produce lithium-ion pouch cells to demonstrate performance improvement, while findings will be presented to different stakeholders in the battery sector.

The new technology will diversify and strengthen the lithium-ion battery supply chains, which have traditionally relied on purchasing current collectors from the Far East.

“This project is a perfect example of how DTF innovates alongside talented partners to meet global challenges such as this need for safer and more efficient batteries. We are delighted to be involved and anticipate making significant progress on the technology during the project” said Dave Wall, Global Technology and Market Development Leader for DTF.

Dr Zlatka Stoeva, a managing director of DZP Technologies says: “The project is a great opportunity to bring our innovation to the battery market. The consortium has a unique set of skills and capabilities which are needed for this to happen, and we are excited and proud to be part of this development”.

Dr Dmitry Yarmolich, CEO of Plasma App says: “The collaborators from Academia, Industry, and Startups with support of Faraday Challenge Fund established a great innovation-driven team. For Plasma App this a great opportunity to scale up the technology to the next industry readiness level.”

Dr John Low, Associate Professor at WMG, University of Warwick says: ‘‘Until now, innovation in the current collectors have not been fully exploited for improved battery performance. It is projects like this that will help accelerate the journey through the discovery platform, prototyping devices and preparing for industrialisation. We are excited to be involved in the project.’’

The UK Government is supporting this project as a part of the £318 million Faraday Battery Challenge for research and innovation projects and facilities to drive the growth of a strong battery business in the UK. Project reference number 98297.

Further information regarding the Faraday Battery Challenge is available via UKRI/Innovate UK:

https://www.ukri.org/news/creating-next-generation-batteries-for-electric-vehicles/

Please contact Dr. Julian Robinson for further information on polyester film developments for Energy Storage applications:

julian.n.robinson@dupont.com